The importance of FIRE safety in Commercial Solar “Electric” Installations ? (Click here for the RESIDENTIAL Version)

If you are considering a “Solar PV” installation on a “building”, whether residential or commercial. Has your consultant or supplier advised you on the difference between having full fire safety or having very little ?

Sep 2023, East London Solar Fire – Before and After. |

Netherlands – 2022. |

The fire on the left above occurred in east London in Sep 2023, and while it is still under investigation, you can see the before photos of the roof of the building.

This shows several issues with the Solar Electricity system and why it was a fire just waiting to happen. Firstly, the panels have moved, which means they were incorrectly ballasted in the first instance.

When solar panels move, the only thing holding them will be the DC cabling, which will now be at risk of failure and Arc faults. Had this system been installed with the correct management and monitoring systems, these issues would have shown up in the reporting long ago, and hopefully, the fire could have been avoided. Also, there clearly was no maintenance or checking of the system as the ballast would have taken months or years to move the way it did. This system was installed with the best intent in the world but nearly destroyed the building.

DC (direct current) faults are the primary cause of fires in Solar PV systems. If you install inverters with no DC isolation or Arc detection/Management built-in, you probably have NO fire protection or preventive management system for the biggest root cause of Solar PV fires.

A DC fault that could cause a fire should be detectable months in advance if it is a DC cabling weakness. This fault can occur during the system installation or during a storm that weakens a DC fire risk over time.

As with all HONE Renewable Electricity systems, Arc Detection, Insolation Detection and ongoing Management of all Inverter functions in real-time ensure maximum safety of all systems.

Q1: I want to install Solar on my commercial or industrial building, what is the first thing I need to do?

For commercial and industrial projects, you first need to contact your insurance company and request their information pack for insurance compliance for adding a Solar Electric system on your roof. It will vary from a simple list to a complex 800-page document depending on the insurer and their history of accidents. If you go ahead without doing this step, your entire insurance could be invalid without knowing it. The design of your system will be done in conjunction with this document.

Q2: What fire prevention measures should I insist having on my installation?

See the checklist and explanation further down the page for greater detail. You should insist that your inverter (s) have (AFDM) Arc Fault Detection and Management and automatic shutdown for Arc faults (these faults will show up as insulation faults months before a fire and may be present from the installation on day one). A premium inverter and management package will act as your fire safety system.

Q3: I assume that fire safety is a mandatory requirement for my power inverters as I am placing them within my building?

Unfortunately, not so much as you might think. The primary function of an inverter is to convert DC to AC, and the inverter will be tested and certified to do that safely, but only within the inverter itself. Specialist features and functionality, such as management platforms, arc detection and protection, and live 24/7 opex and maintenance, are all premium functions that provide additional safety on the DC and AC equipment “outside” the inverter and are only found on the best premium inverter equipment.

This is compounded more in commercial and industrial installations where you can have cascades of inverters in one project.

| CHECKLIST FOR INVERTER FUNCTIONALITY FOR FIRE PREVENTION |

|

| Insulation Resistance Monitoring (Inverter Function) |

This is a function of monitoring the DC cabling system and the earthing outside the inverter. This is an additional non-standard fire safety function of premium inverters and is there to detect the inadequate installation of DC cabling and/or new faults that occur over time. These faults can eventually turn into fires if left uncorrected, but in this case, they will shut down the inverter and force you to correct the issue well before any fire risk. These faults can result from the installation, mismatched DC connector fittings or poor assembly of the DC cables. Always ensure that the total system package comes from only one supplier. All HONE systems come with this functionality as standard. |

| When the installer runs thousands of metres of DC cabling in a project, much of it hidden, it is virtually impossible to have perfect DC connections and cable outcomes each time.

This is why insulation resistance monitoring is key once you turn on the system to keep checking the integrity of the DC cabling in every project.

For the first three months after switching on, intense monitoring of all DC Cabling is a must, especially when it rains, to identify if any insulation detections have been identified. In the case of HONE systems, the inverters will shut down automatically until this is done if these are ignored or not addressed. |

|

| Management & Reporting (Inverter Function) |

An inverter should have a reporting function that automatically alerts you to any issues in your system, both inside and outside the inverter itself. All HONE systems come with this as standard. |

|

|

|

|

| Arc Fault Detection (Inverter Function) |

If you place Solar PV power electronics in or around your building, Arc Fault Detection is like having your own fireman on site. It is designed to stop the risk of fire before it can happen and shut down the inverter, and isolate the DC supply. You should not get to this point if you have Insulation Resistance Monitoring. However, you may have an immediate failure of a DC connector or animals/rodents, which eat into cables and cause an arcing fault. The inverter with AFDM will shut everything down instantly for safety and isolate the DC supply. All HONE systems come with this functionality as standard. |

| INSTALLATION CHECKLIST FOR FIRE PREVENTION |

| Have all the parts for the installation, including all DC & AC electrical components, come from the same source? |

This ensures all electrical components are high quality, compatible and won’t leak or allow water ingress. |

| Has your inverter got a long warranty, 20 years minimum? |

The inverter is a high-cost component in the system; inverters with short warranties that are low cost don’t generally have a lot of functionality. Your exact inverter model is also unlikely to be available when the warranty period is over, and a full re-design of the system will be necessary to get it running again. |

| Has your system installer a full-string design plan for your system from the supplier? |

You need to store this electrical plan for the future; it will be needed to fix, diagnose or upgrade/repair your system. |

| Is the supplier and/or manufacturer providing you with direct, full online and system support for the duration of the warranty period (free) |

These systems are complex, and you should have supplier and/or manufacturer product support for the life of your system should you request it. If your system stops working in year 3, what do you do ? The existing installer may no longer be in business; where do you go? Who holds your warranties for the system, or did they die with the installer? |

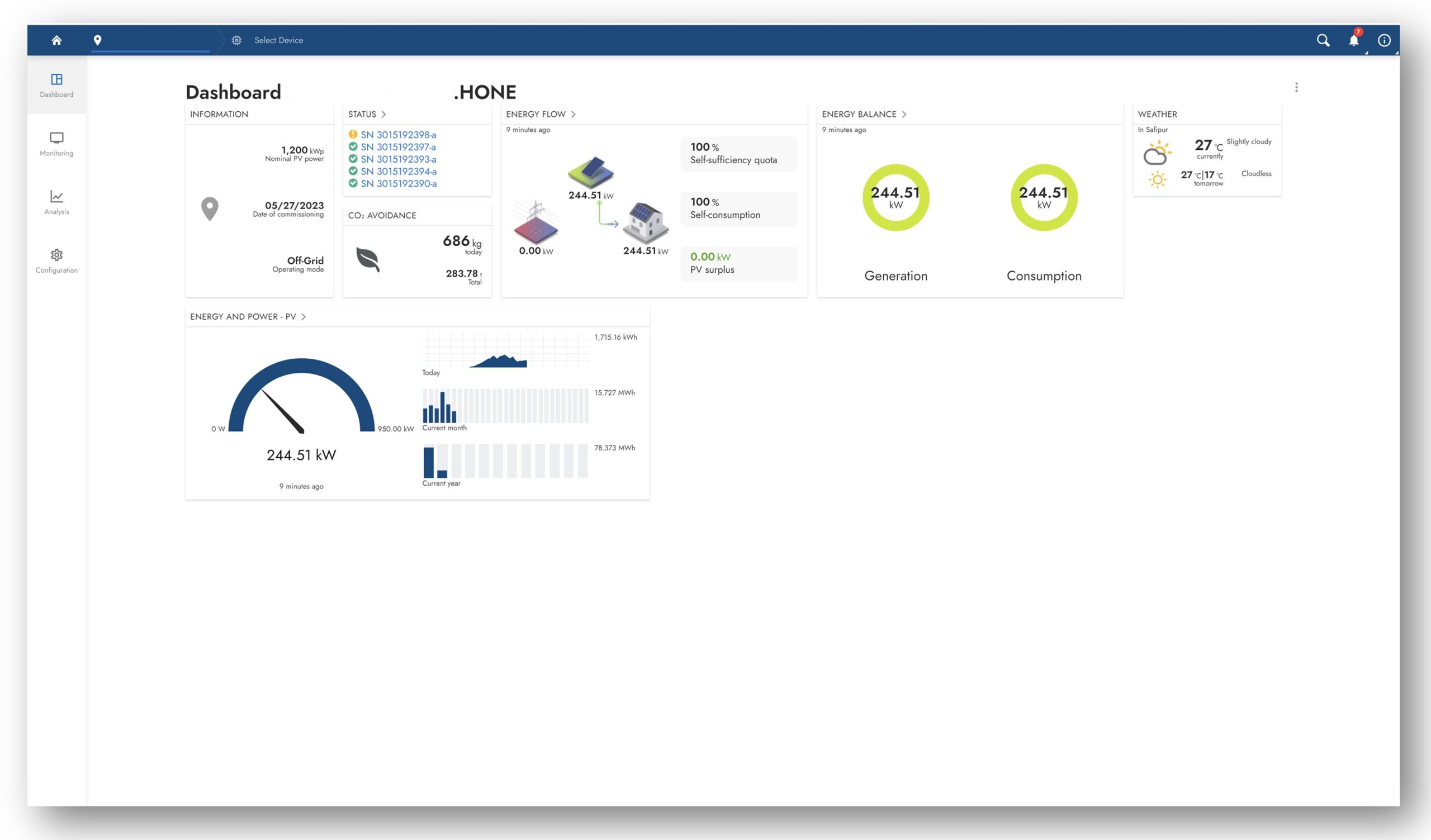

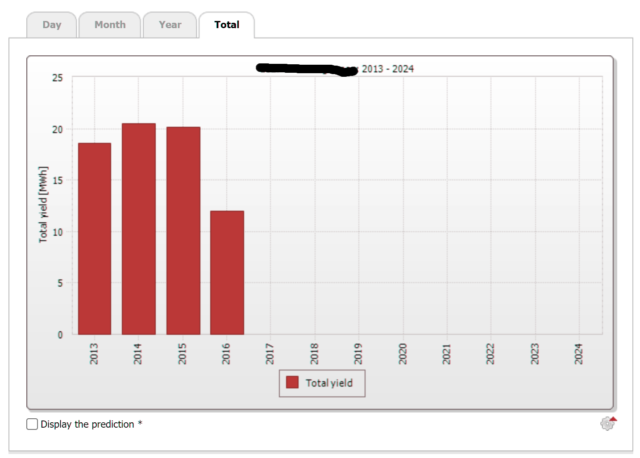

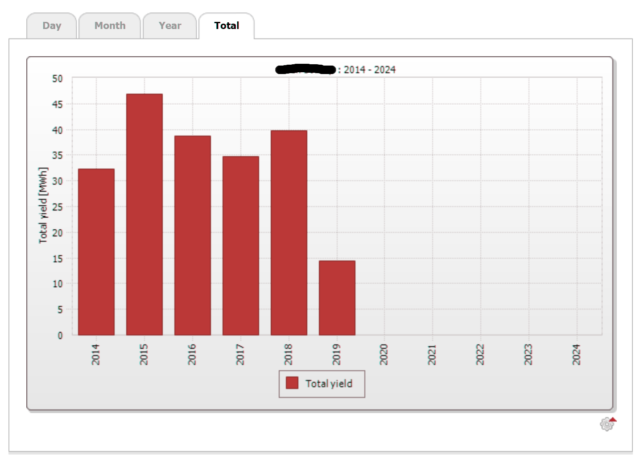

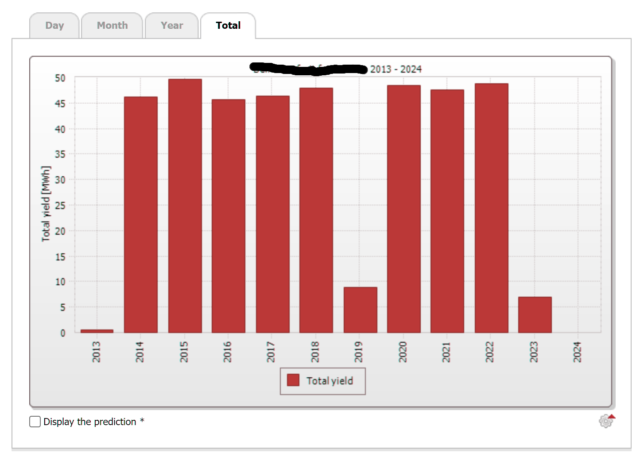

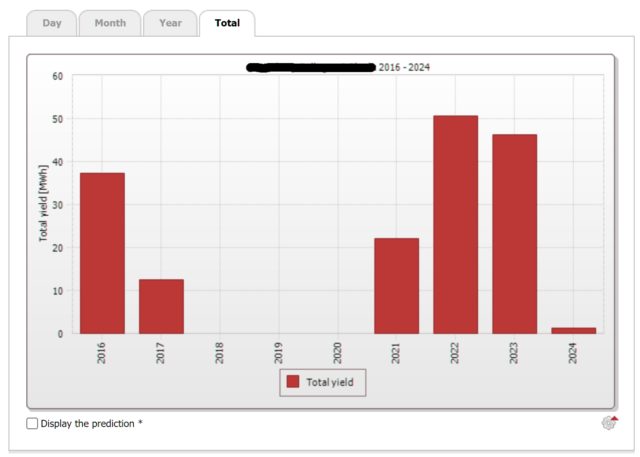

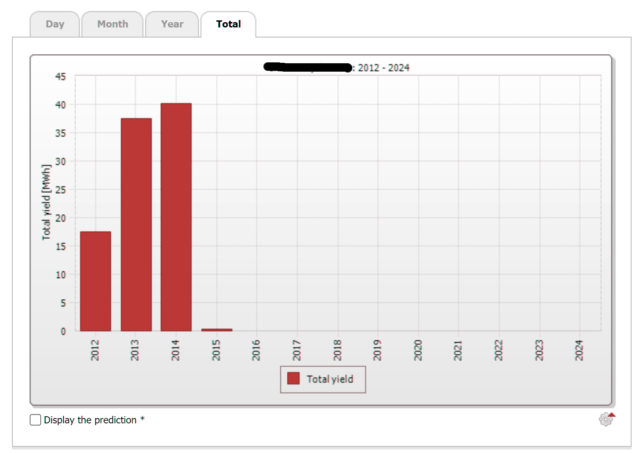

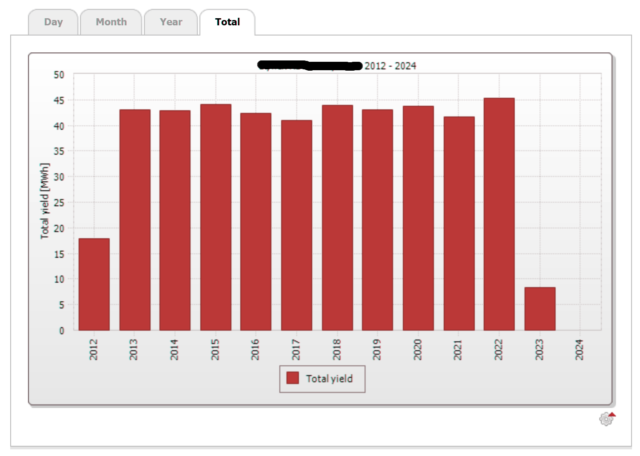

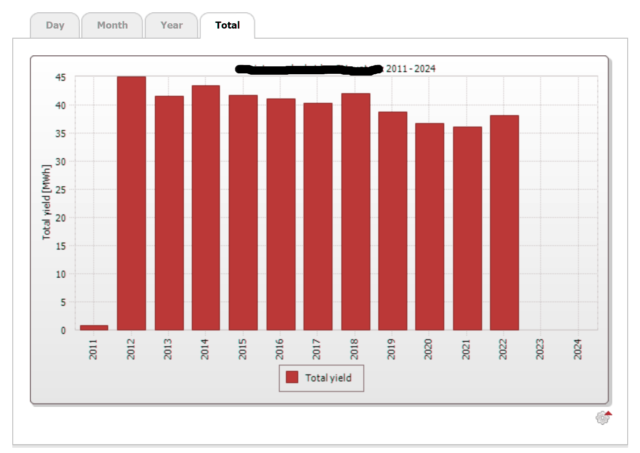

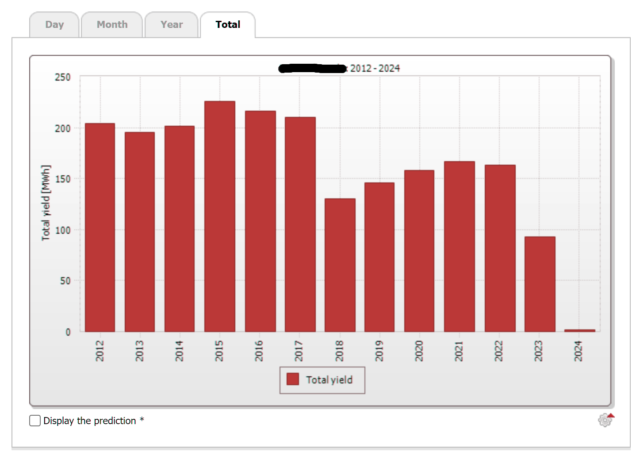

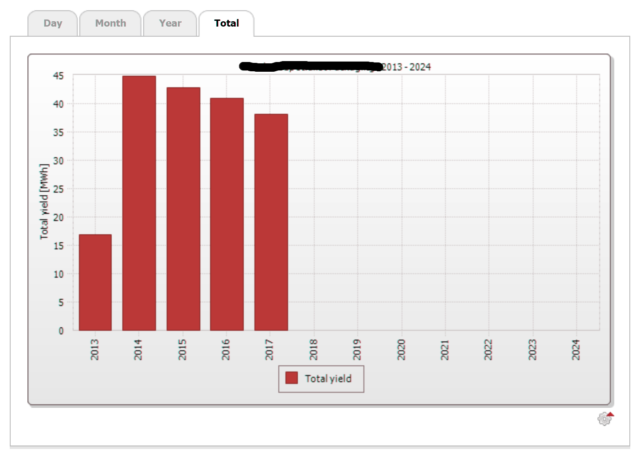

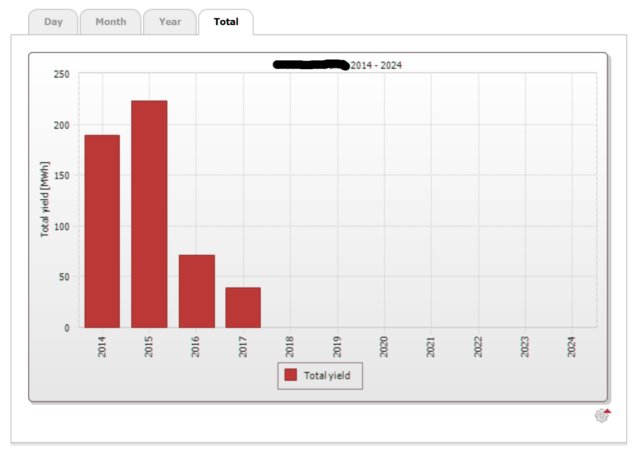

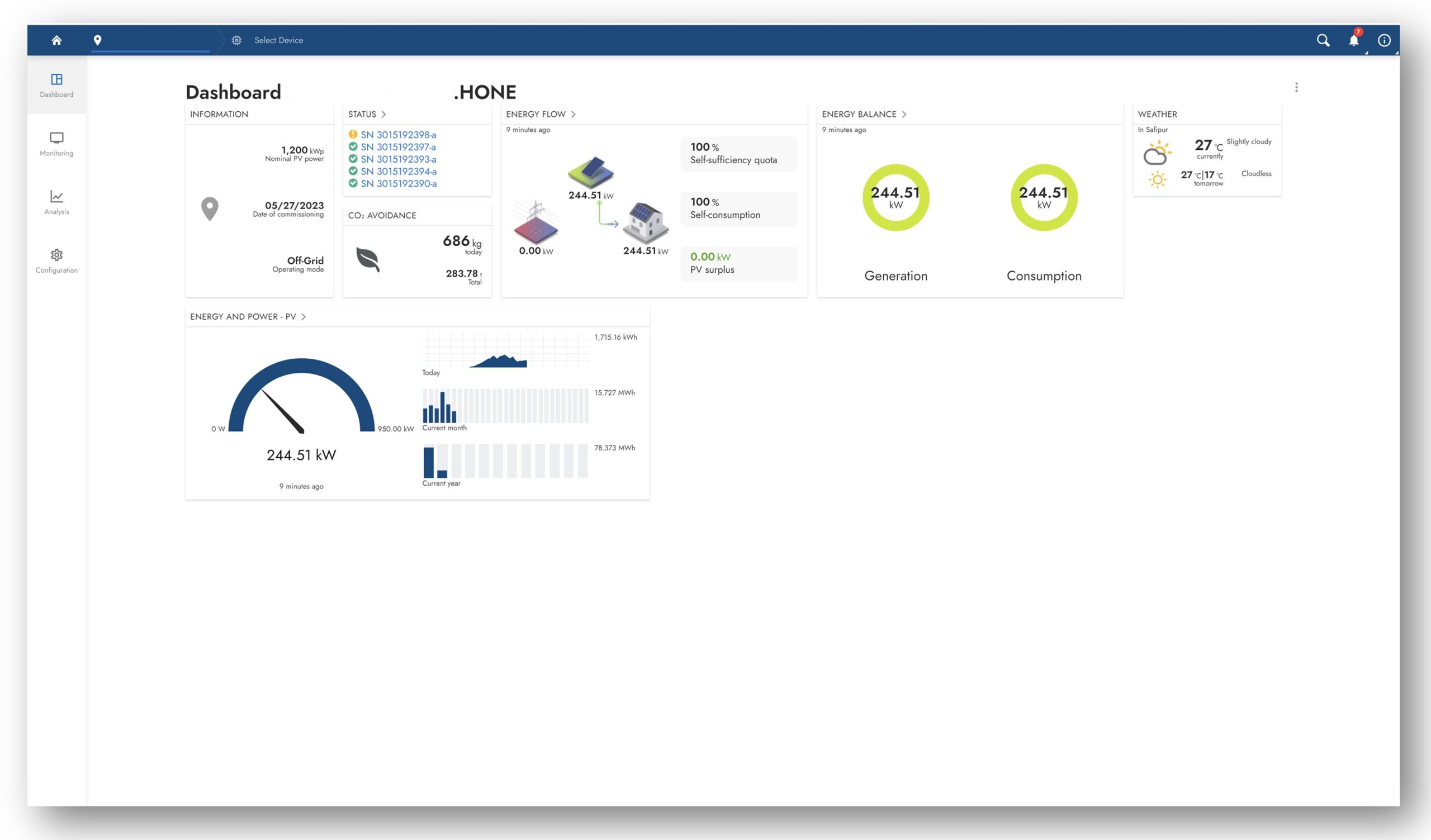

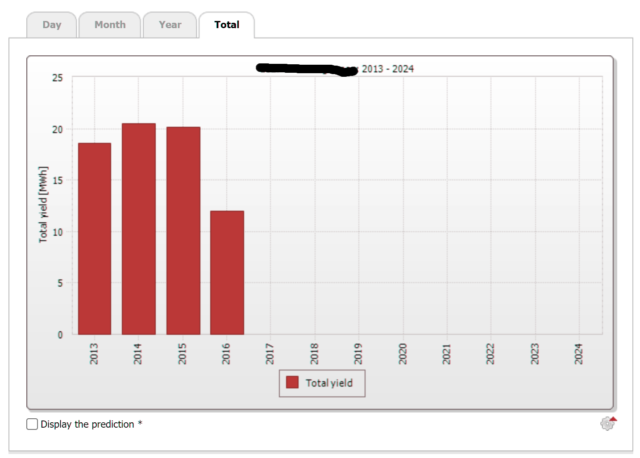

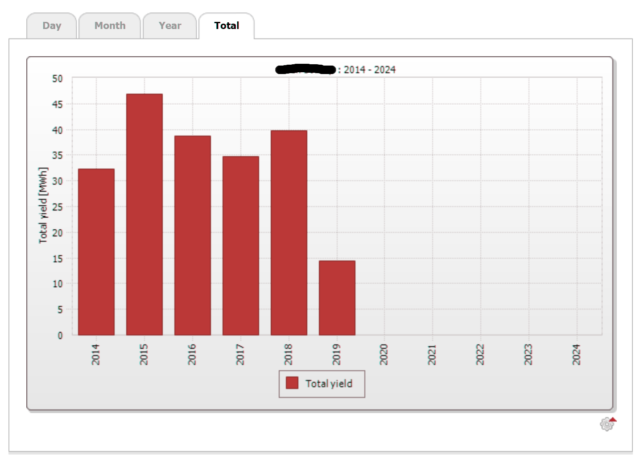

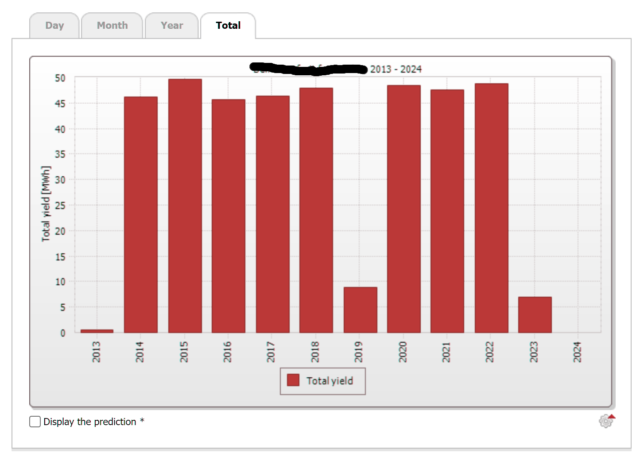

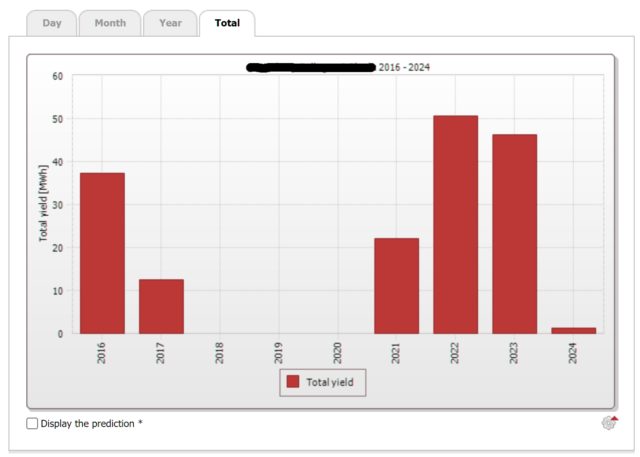

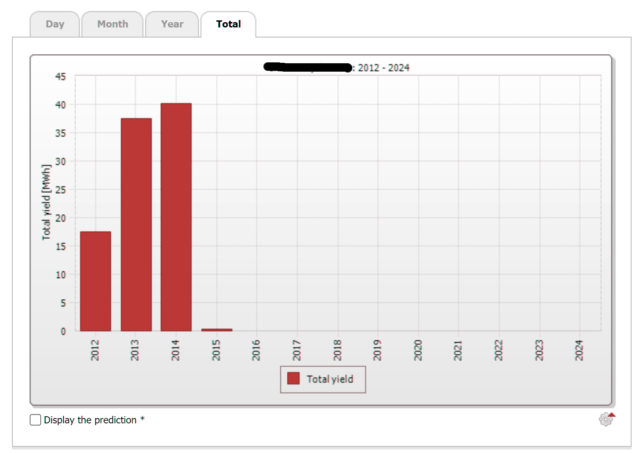

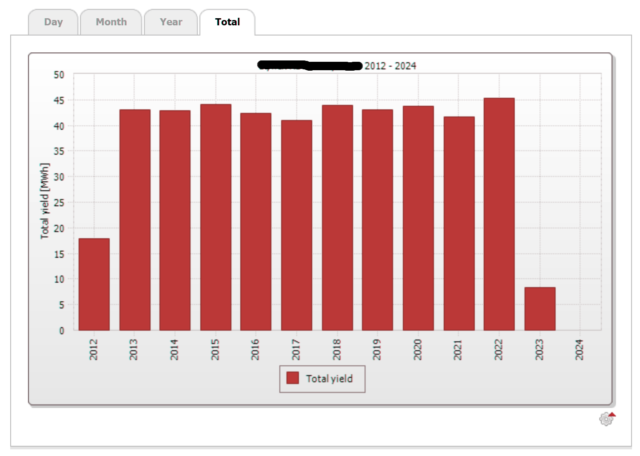

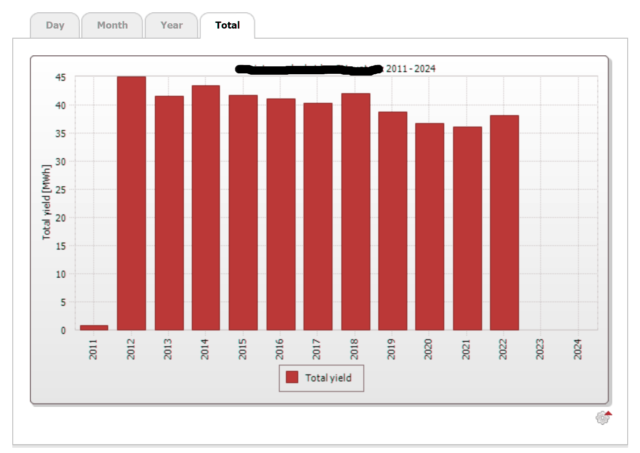

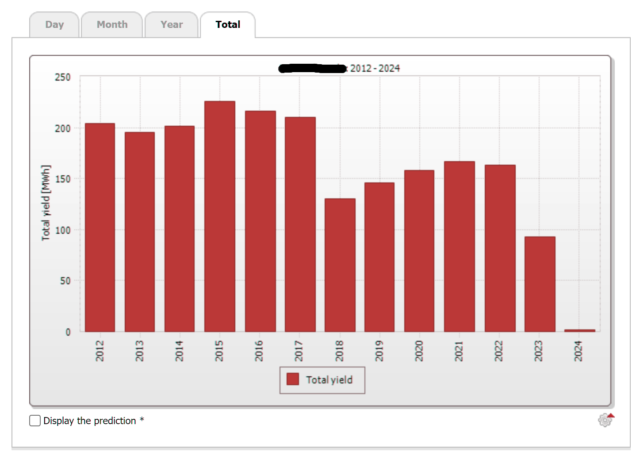

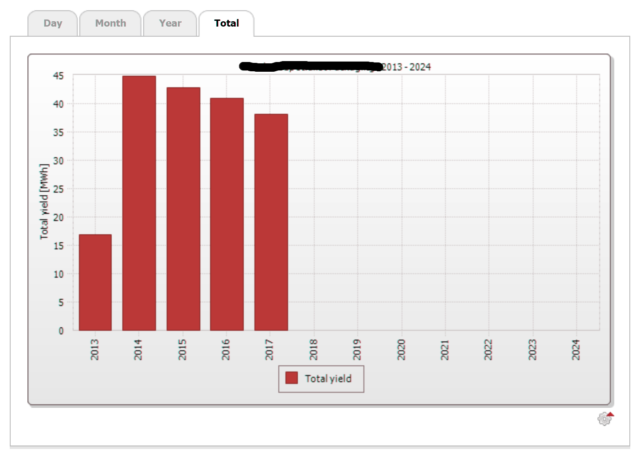

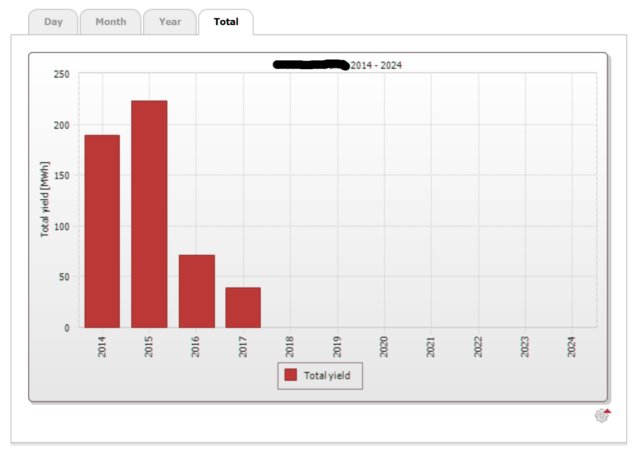

| If you believe that once your Solar PV installation is installed, you can sit back and watch the money roll in for the next 30 years, you may be in for a shock. The following commercial and industrial systems from Ireland and the UK below have been screenshots from the public internet. These are a small sample from 5/2/2024, but today, thousands of systems show similar worrying issues.

We do not know what equipment is used in the systems below, but the issues are obvious. There are various issues; reduced annual performance is a big worry for damaged DC cabling or panels. System dead could be a shutdown or failure of the inverter. If your inverter only has a five-year warranty, there is a reason. Many of these installations have been allowed to run in circumstances that needed investigation and could be deemed high fire risk. Always ensure you have the best power electronics installed in or around your building. Yes, it will be more expensive equipment, and it is designed to stop your building from having a Solar PV fire in the first place.

Based on the data below, all of these systems, whichever make or brand, were bad investments and should have had maintenance interventions. As reported recently, tens of thousands of solar installer companies have exited business in the UK, meaning the warranties on systems like this probably went with them.

All HONE systems are kitted completely by HONE and delivered as full packages to our partner installers. This ensures we can support your system throughout its operating life and protect your investment regardless of what happens to the installer. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

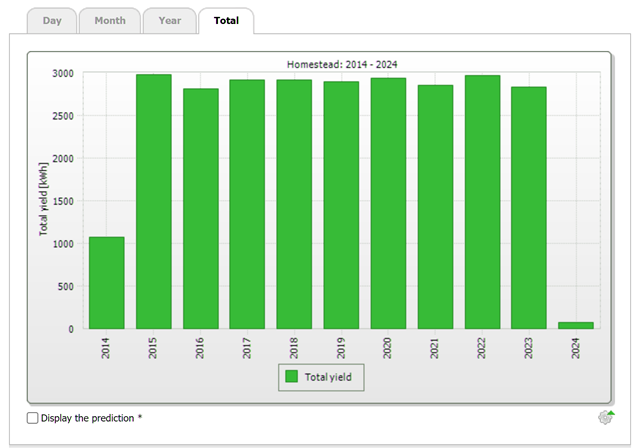

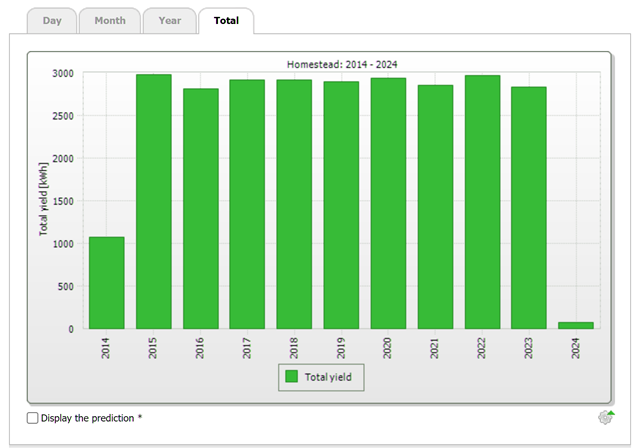

This is what a system’s output performance should look like. Each year should be nearly the same as the last (except year one, which will be a part-year).

But manufacturer warranties must back it up, or your investment may be well-intentioned but never realised.

|

|